Cold & Hot Kiln Alignment

We precisely measure the actual kiln axis, kiln slope, individual elements, shell deformation, ovality, tyre and roller diameters, and roller skew using state-of-the-art technology. We meticulously analyze all the gathered data with specialized software and present a comprehensive, clear, and easily understandable report.

Understanding the current conditions is the most straightforward approach to prolonging the kiln’s efficiency and lifespan.

Analyse All Details

Inspecting a rotary kiln demands a higher level of knowledge and expertise compared to standard survey services. Utilizing advanced technology, precision equipment, professional data analysis, and our extensive experience in understanding kiln behaviors, we can identify and address issues effectively.

For more measurement, analyze and reporting details, please review our sample hot kiln alignment report. >>>

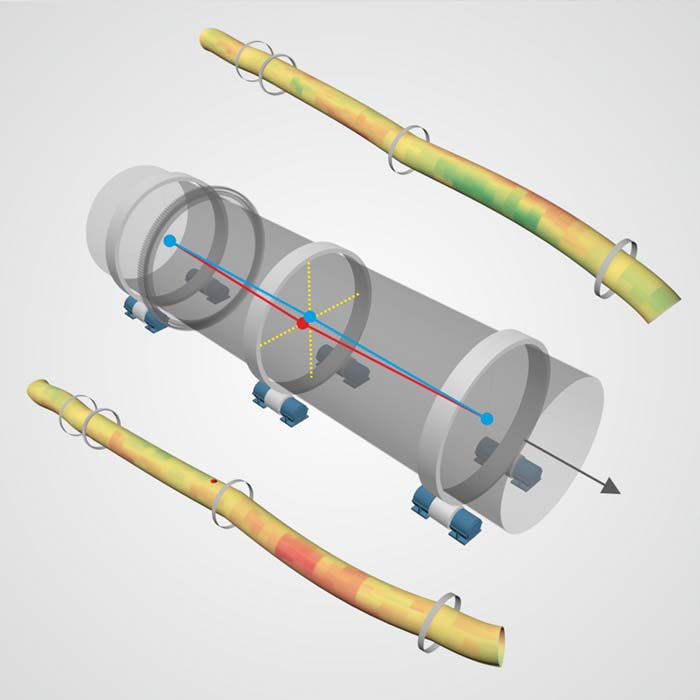

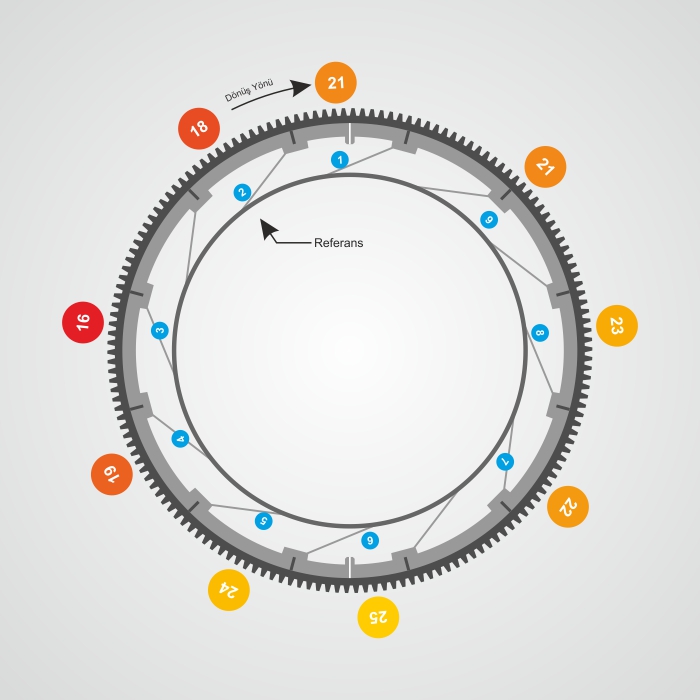

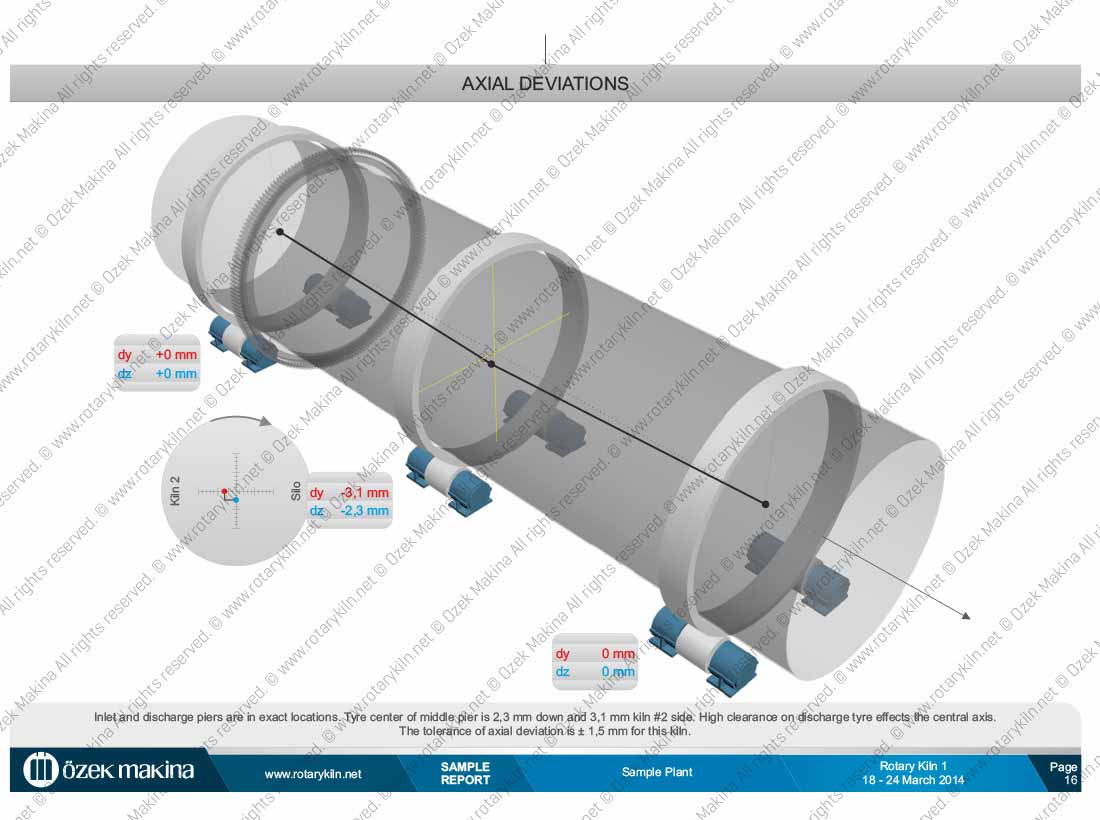

Kiln Axis

We determine the actual kiln axis based on the positions of the roller and shell, ascertain the kiln slope, and analyze individual components like rollers, tyres, pinion, and girth gear. By scrutinizing deviations, we identify the necessary actions to achieve a perfect realignment of the kiln.

These precise surveys benefit from over 50 years of experience coupled with advanced engineering skills.

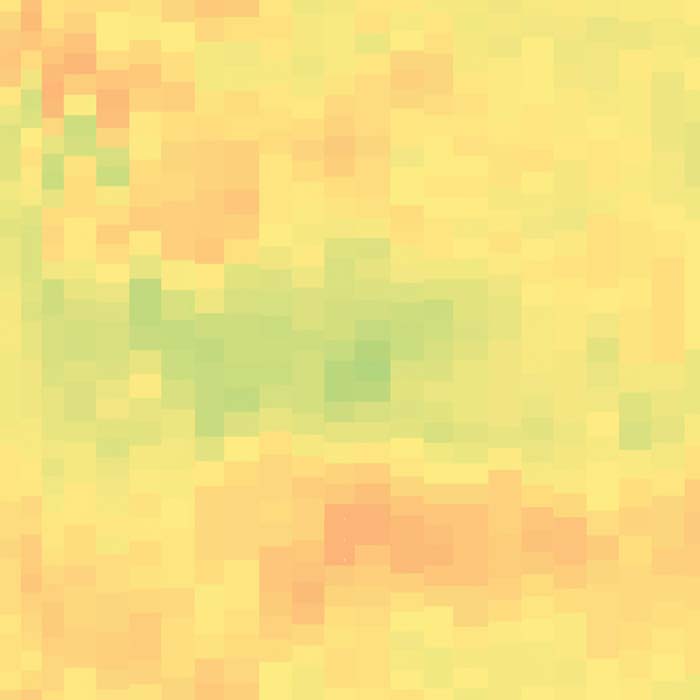

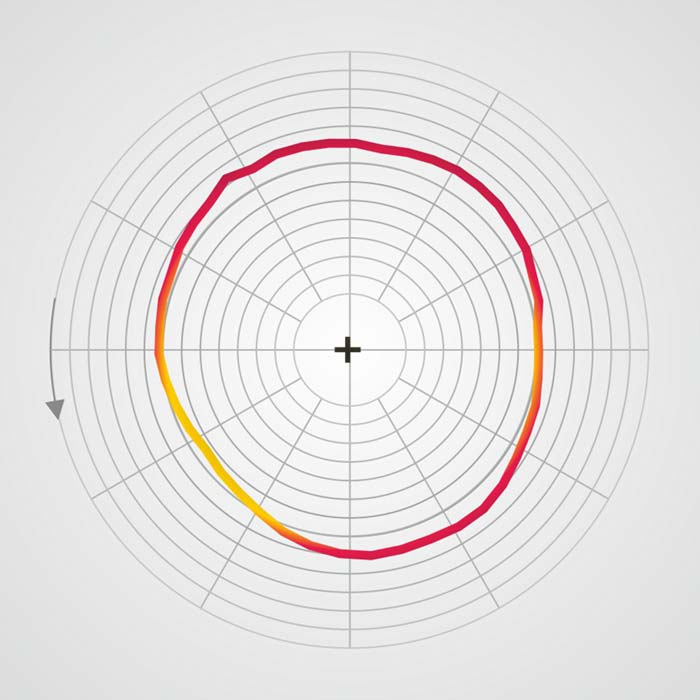

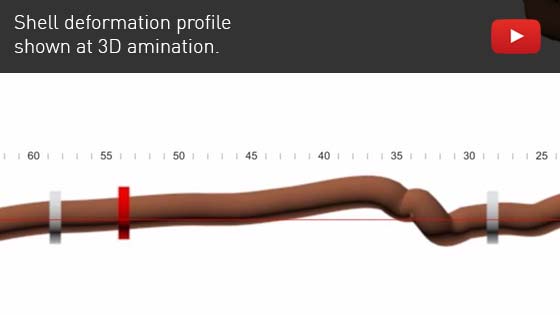

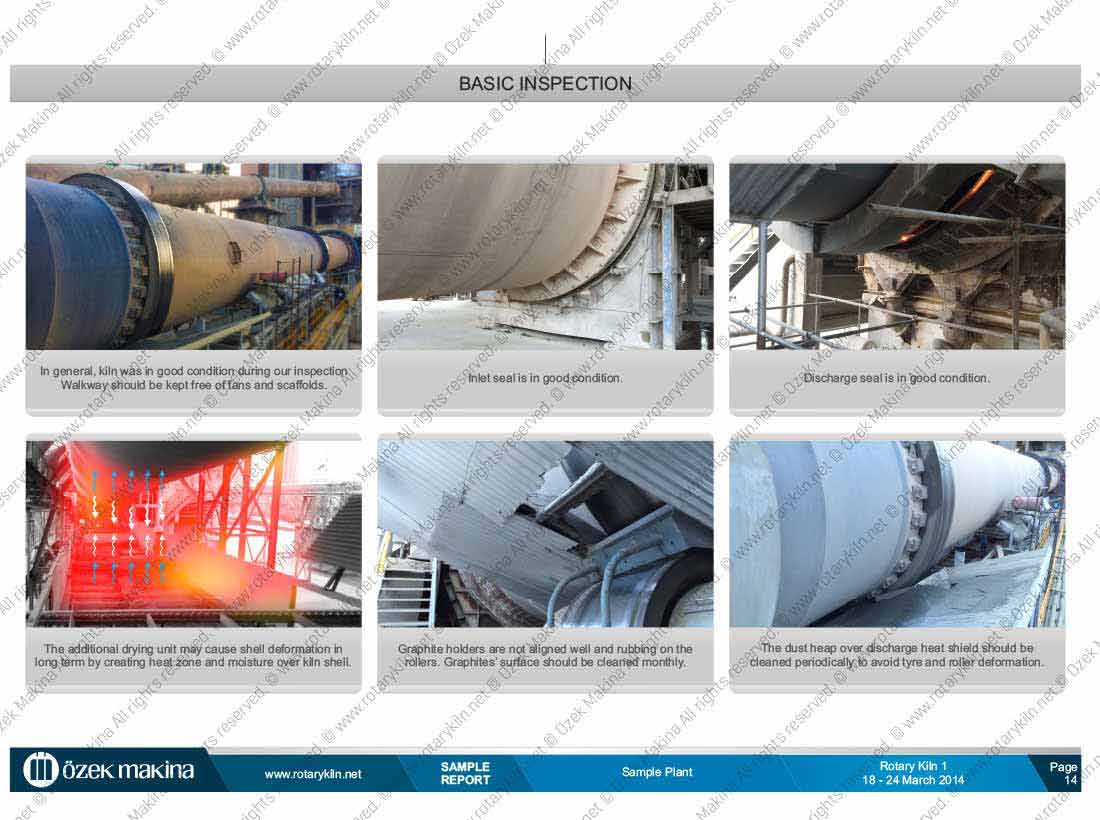

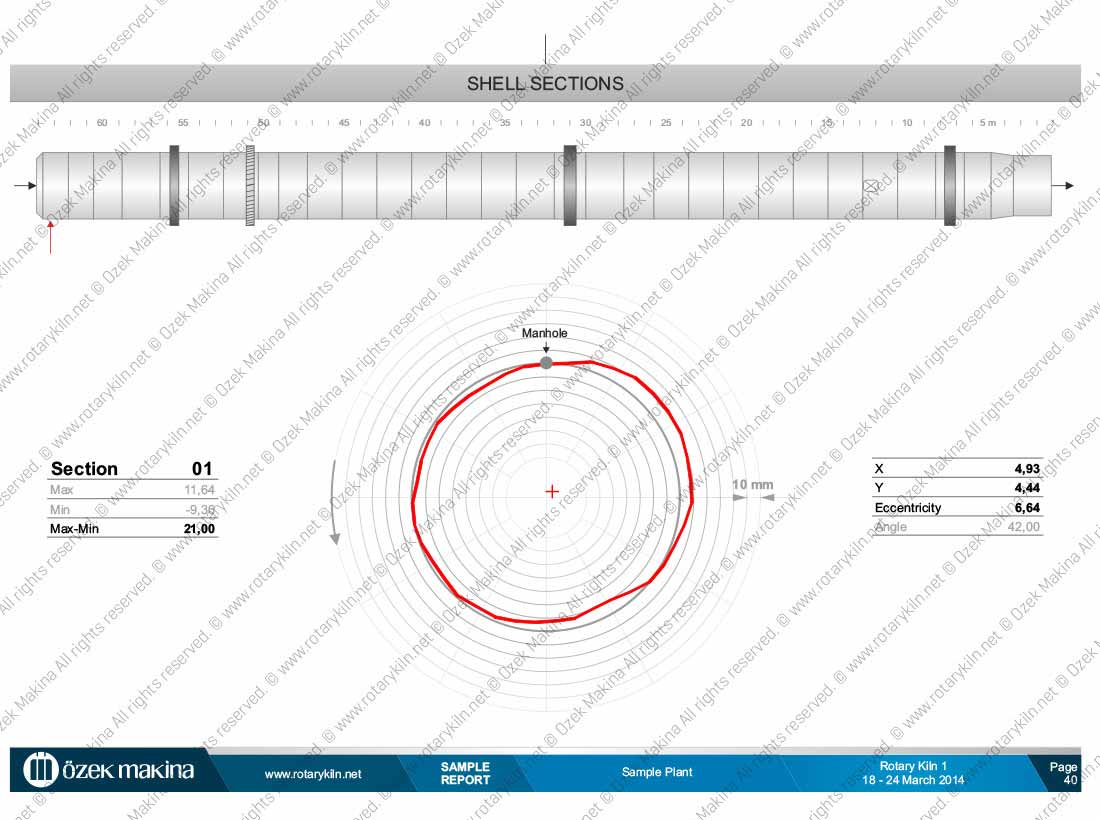

Shell Inspection

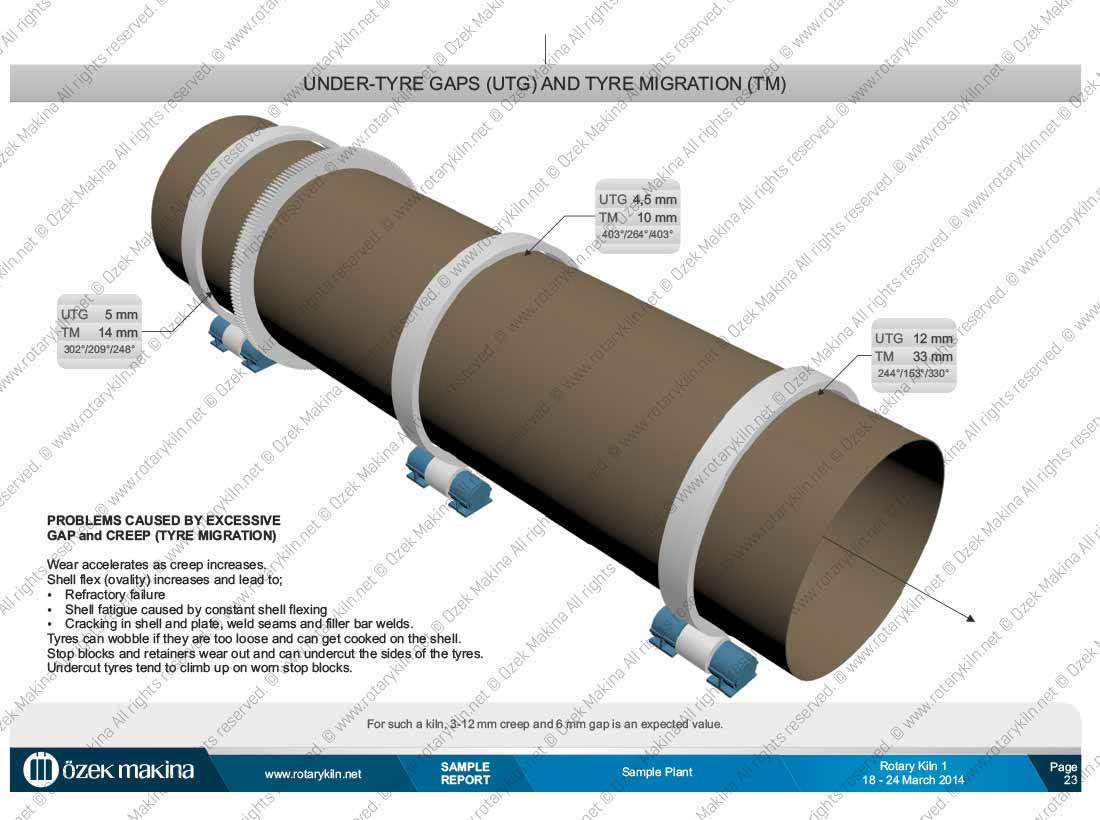

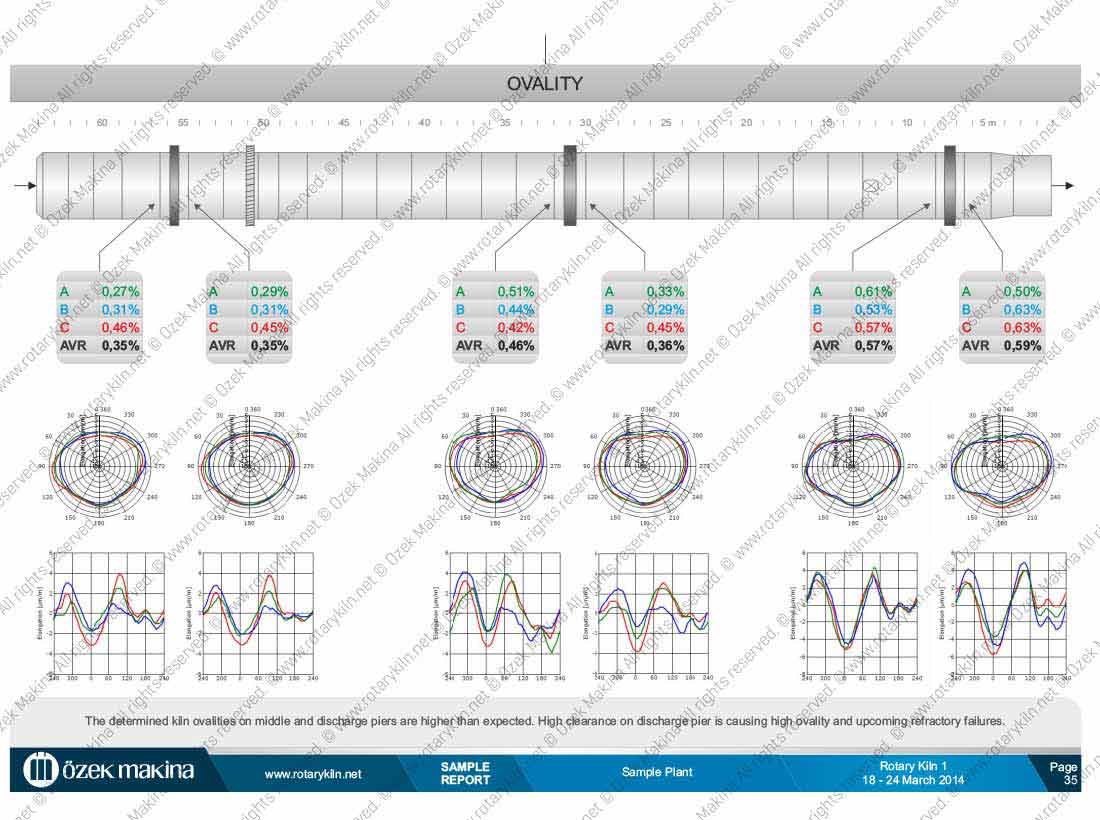

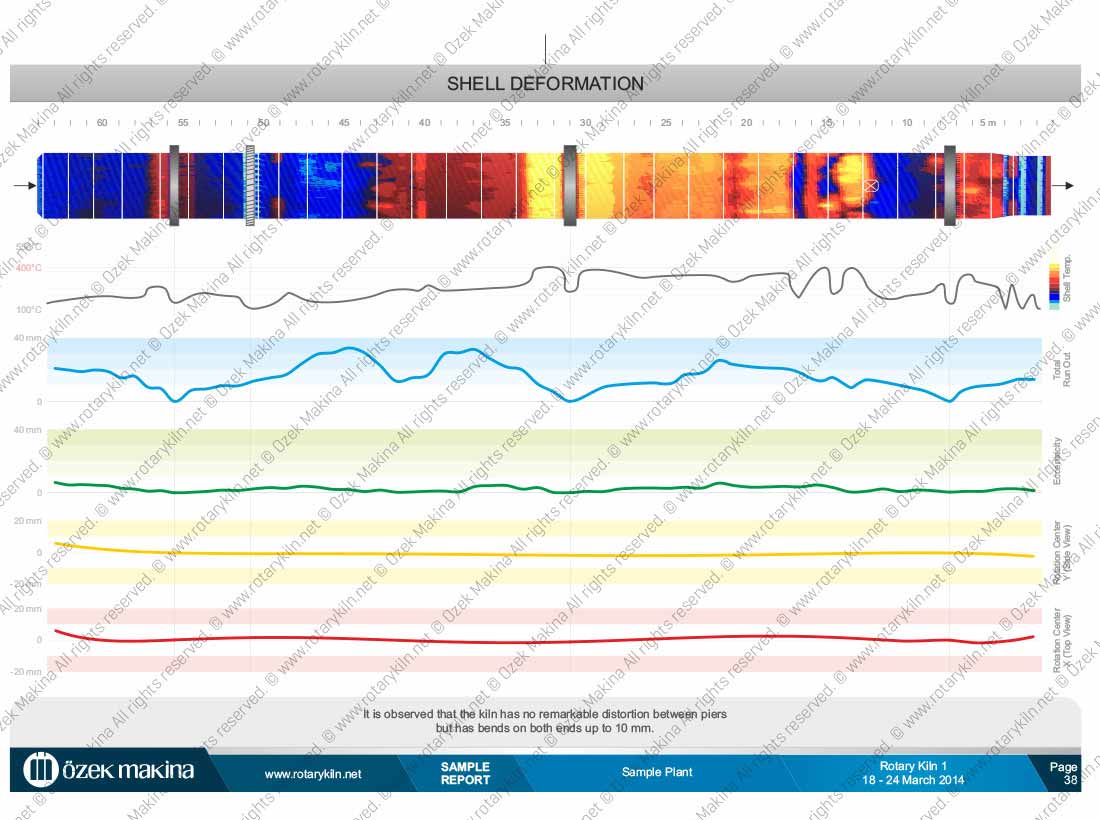

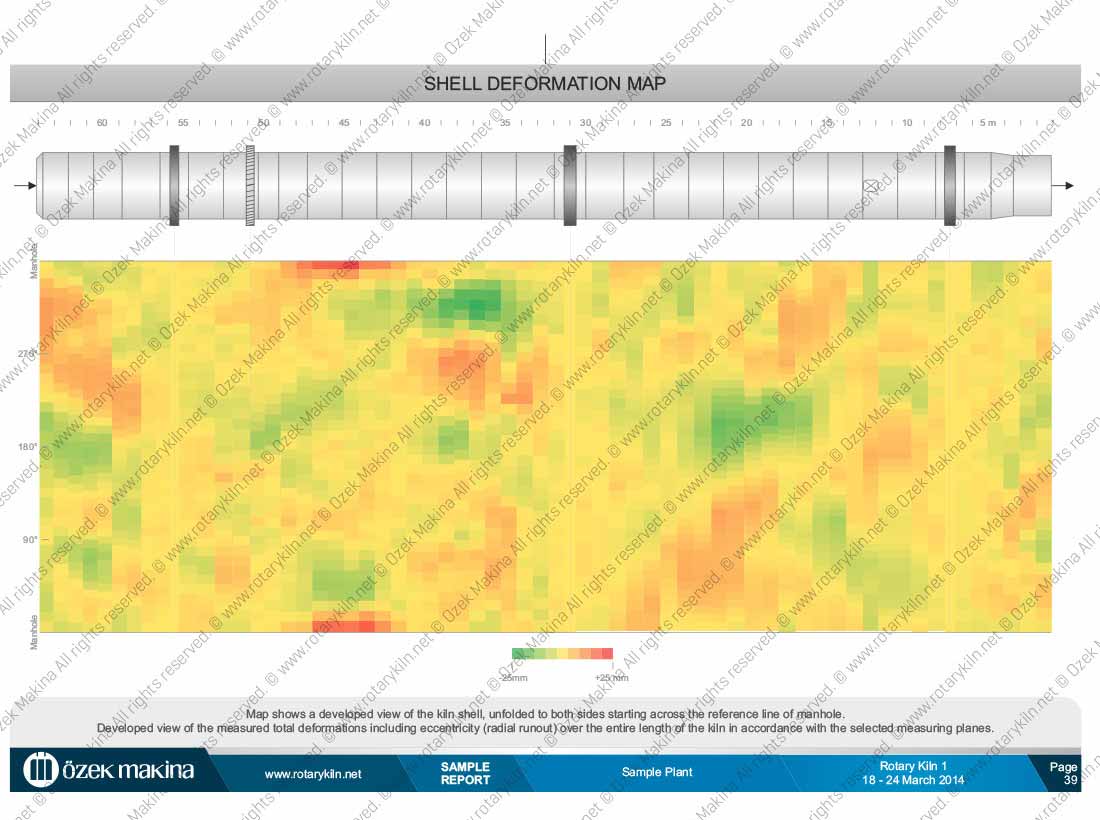

We systematically scan the shell section by section to acquire deformation data, encompassing both plastic behaviors (like collapses, cranks, and eccentricity) and elastic behaviors (such as ovality). Through complex analysis of the shell, shell/tyre relations, and kiln axis, we strive to prolong the life of the shell and bricks.

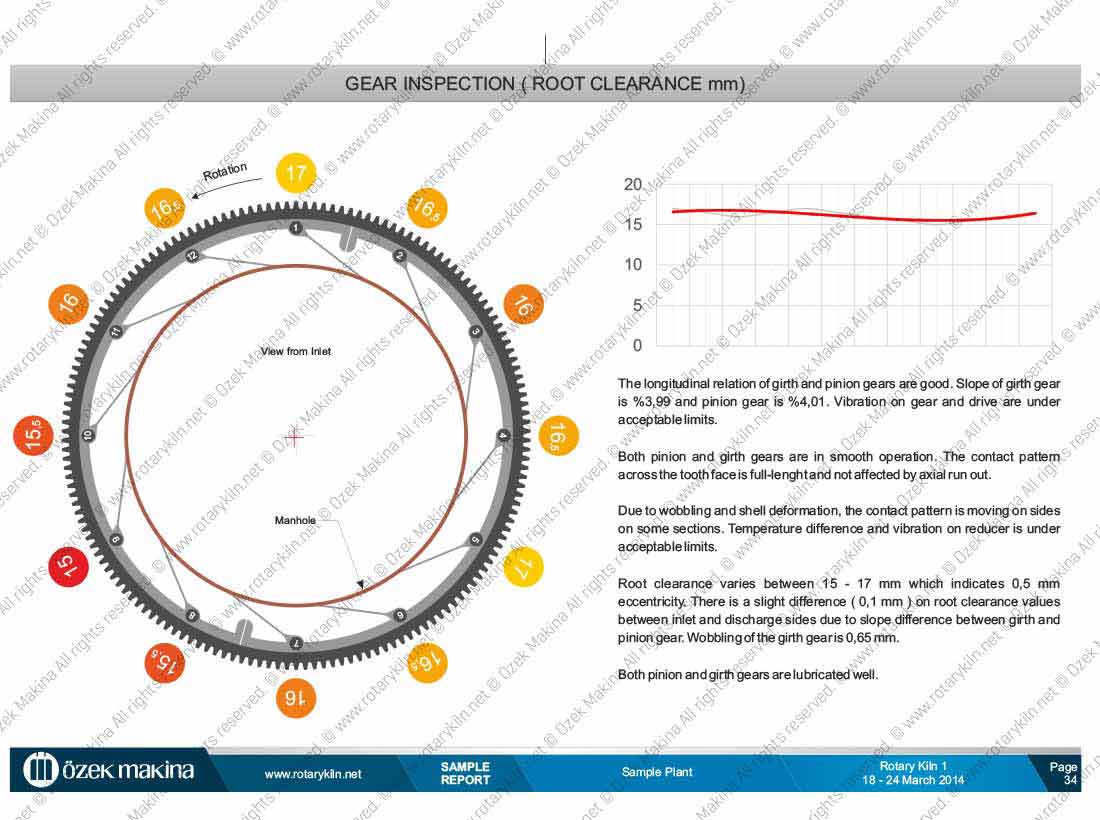

Additionally, we validate load distribution and assess pinion/girth gear relations.

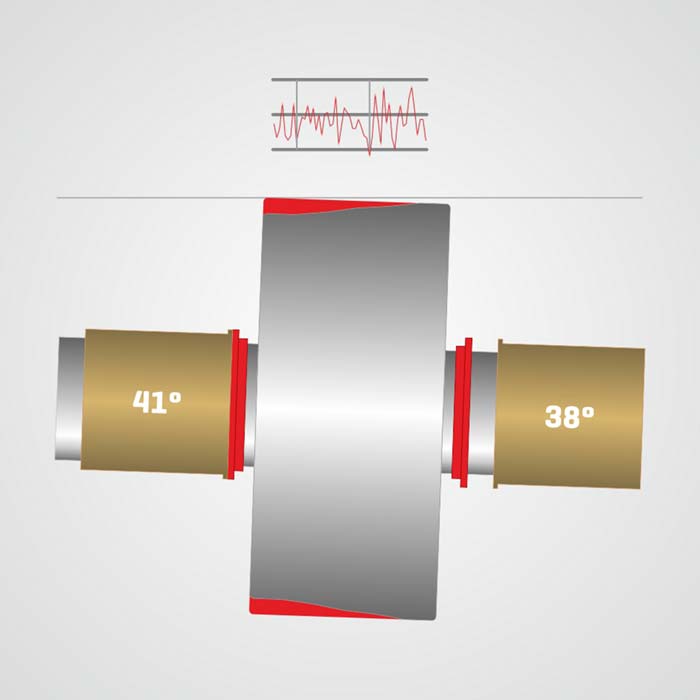

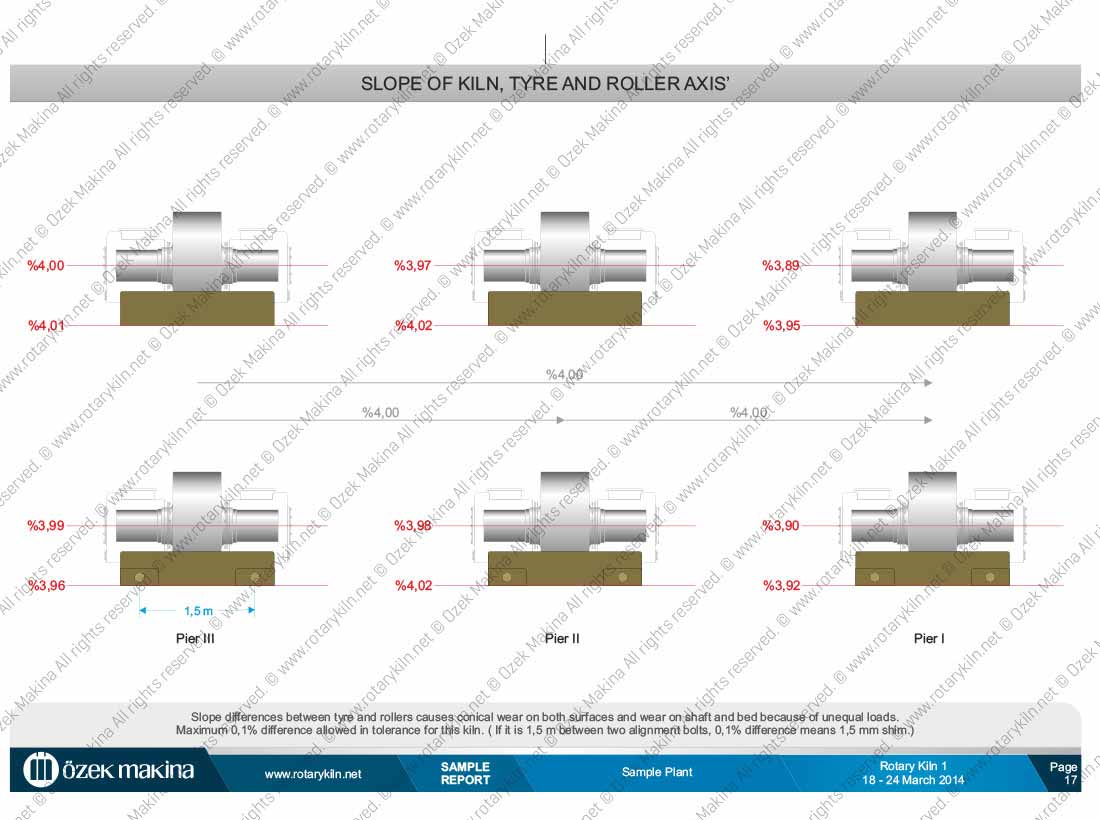

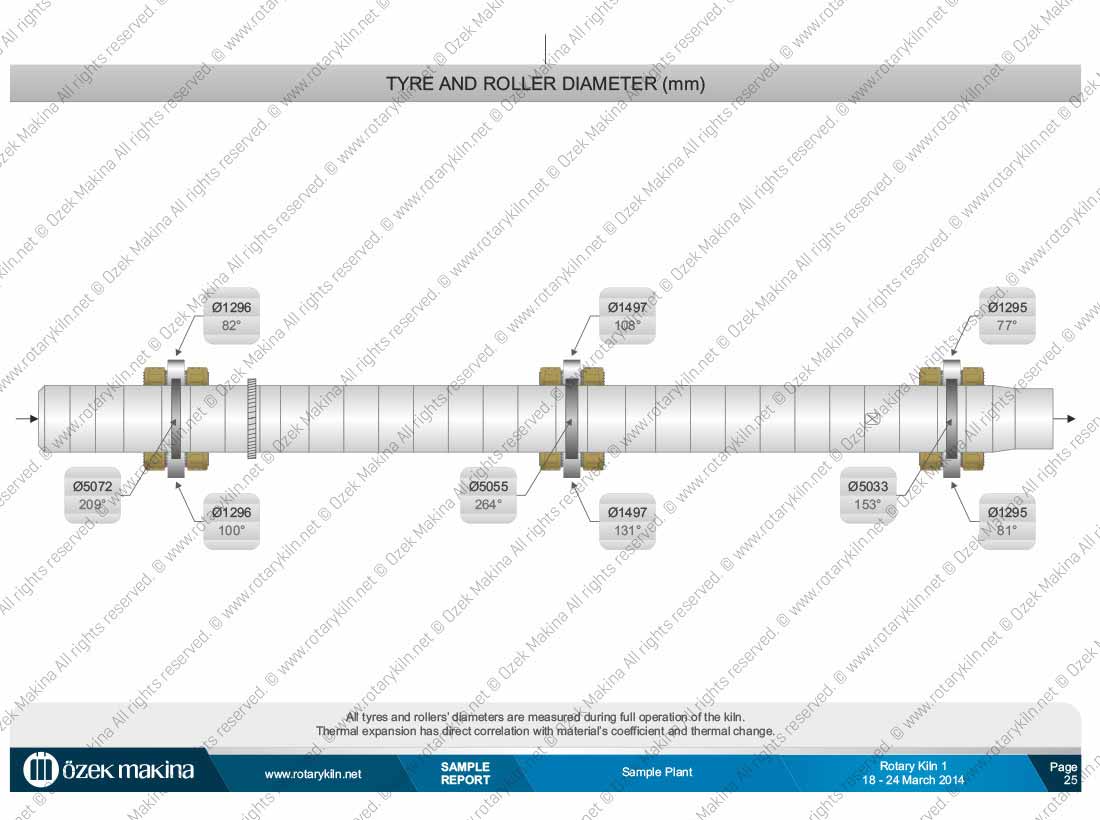

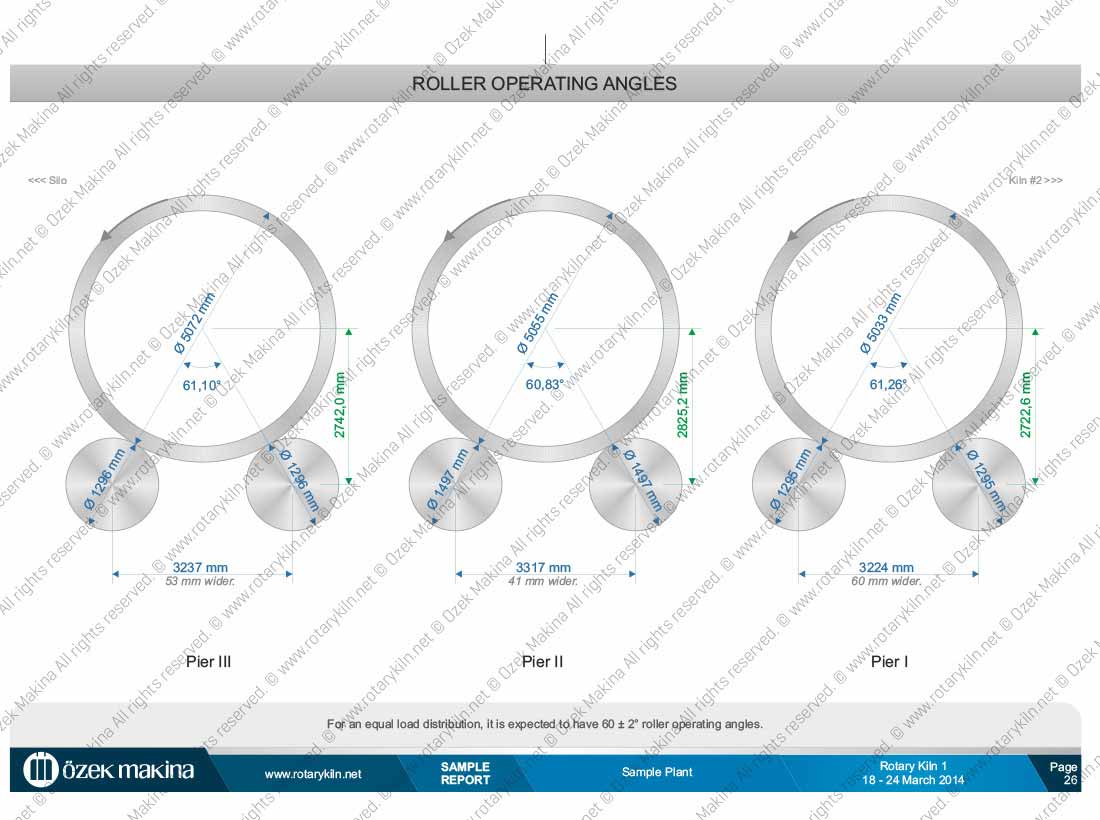

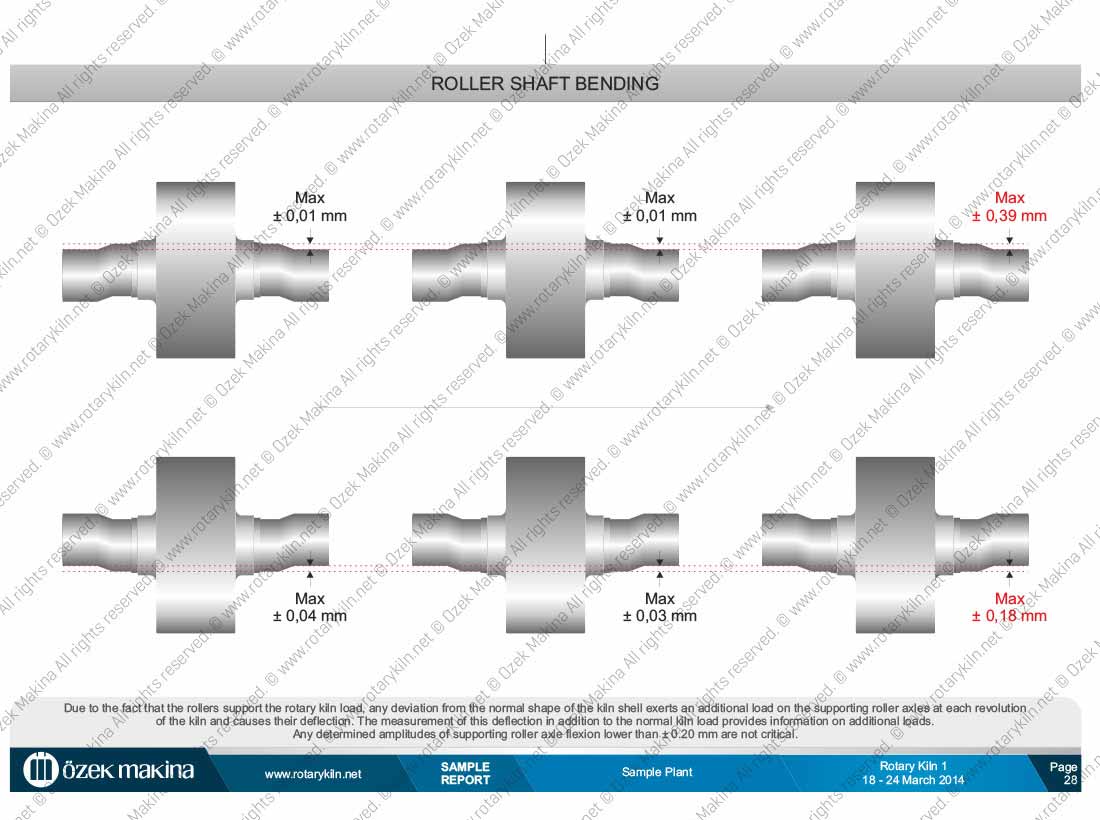

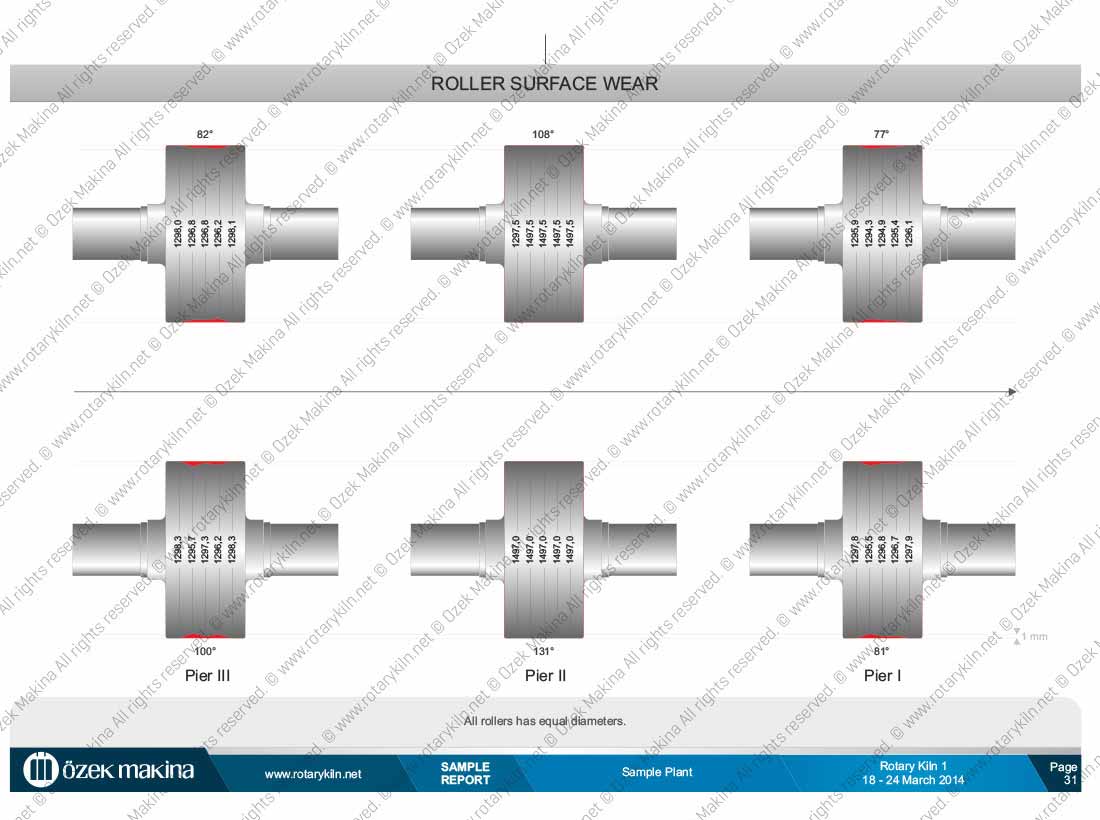

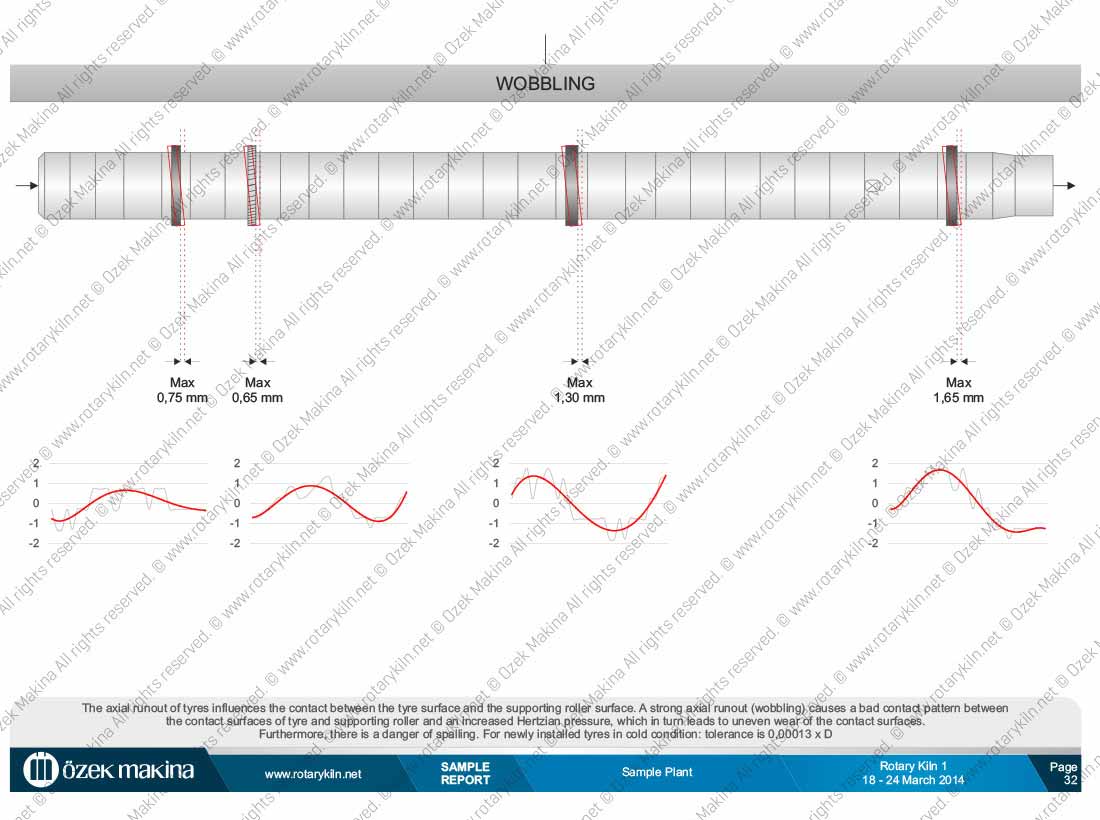

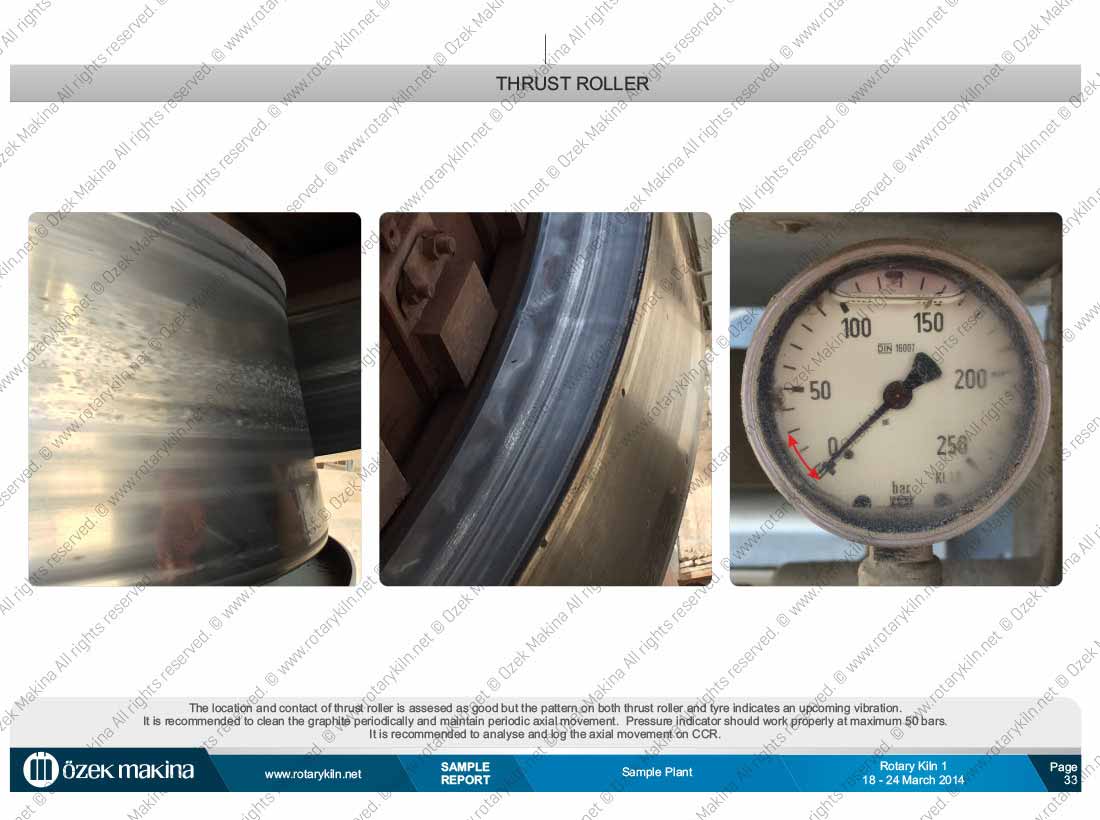

Tyre & Roller Inspection

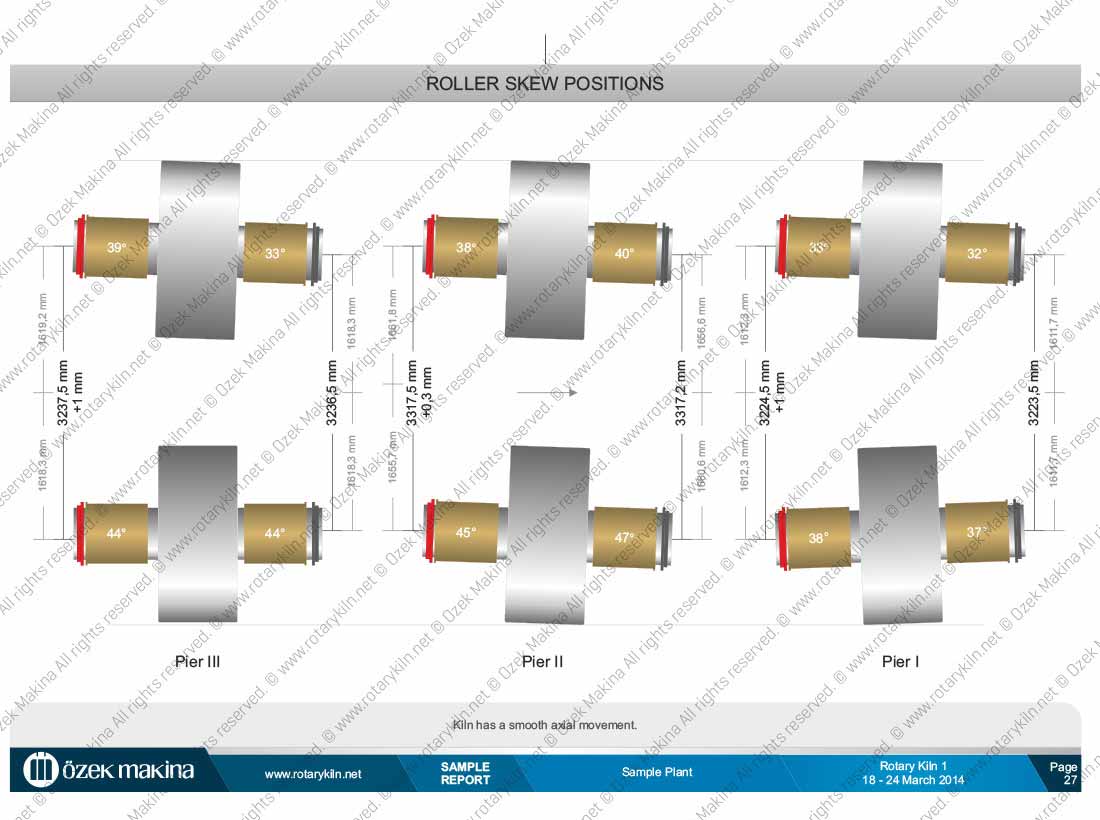

The axial migration of a rotary kiln is primarily linked to the relationships between its tyres and rollers. Through a thorough analysis of information, including the surface conditions and wear levels of both tyres and rollers, bearings, lubrication efficiency, and operating angles, we obtain a high-resolution snapshot of the current condition. This detailed assessment aids in suggesting more realistic alignment actions.

Clean Report

Upon gathering kiln data, we promptly generate and share a preliminary report while still on-site. Subsequently, we arrange a meeting with all pertinent engineers to deliver our findings through a comprehensive and comprehensible report. Supported by high-quality graphics, charts, visuals, and animations, this presentation provides an opportune moment for in-depth discussions regarding ongoing issues, our proposed solutions, and the exchange of valuable kiln maintenance insights.

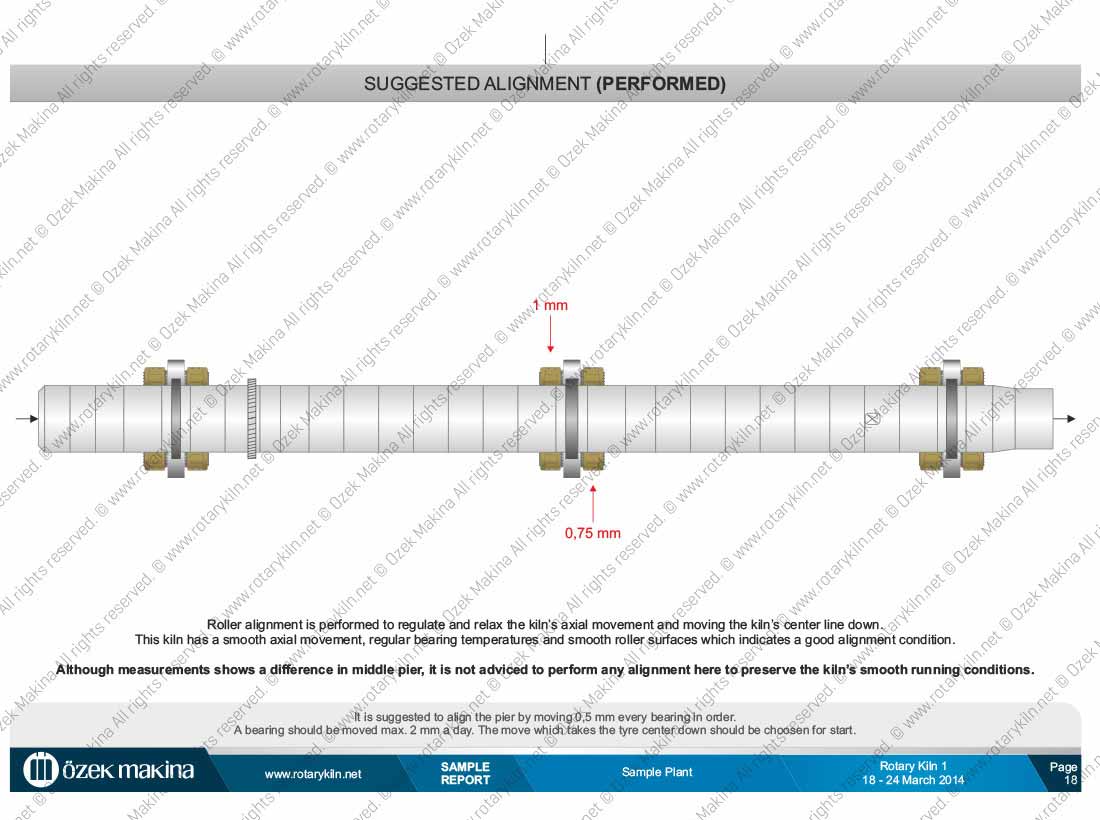

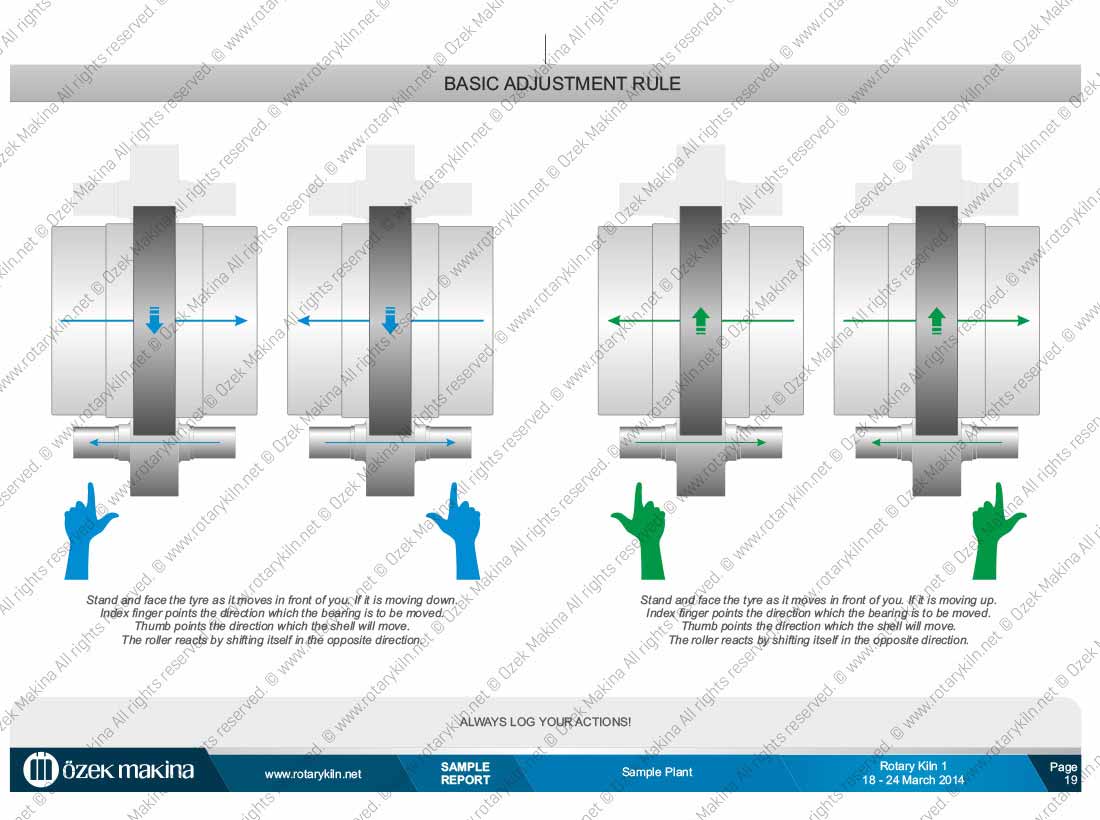

Roller Skewing

Following the presentation of our report and mutual agreement on solutions, we offer supervision services for alignment, encompassing roller skewing and, if needed, bearing replacement.

Our supervision services can be extended to cover shell, tyre, chairpad, and girth gear reversal or replacement. Depending on the request, we can act as a third-party inspector with survey services or serve as a direct supervisor as a subcontractor.

Periodical Services

Our conviction lies in identifying problems before they impede your operations. To facilitate this, we offer regular site visits and kiln services, encompassing fundamental inspections for tyres, rollers, bearings, thrust rollers, shell, and seals. Basic surveys and alignment supervision are conducted at intervals of 3, 6, or 12 months, tailored to your specific needs. For further details about our periodic services that best suit your requirements, please get in touch with us. >>>