Özek Makina offers the unique American Anion® Slick Bar® tyre bore lubricants.

100% Lubricant

~ 40% Graphite

~ 10% Copper

~ 50% Binder

* Contains no chlorine, bromine or other halogens that create health risks.

540°C Auto Ignition Point

Melting Point: 50°C

Auto-Ignition Point: 540°C

This ensures worker safety and no dangerous flame-ups.

Homogeneous Lubrication

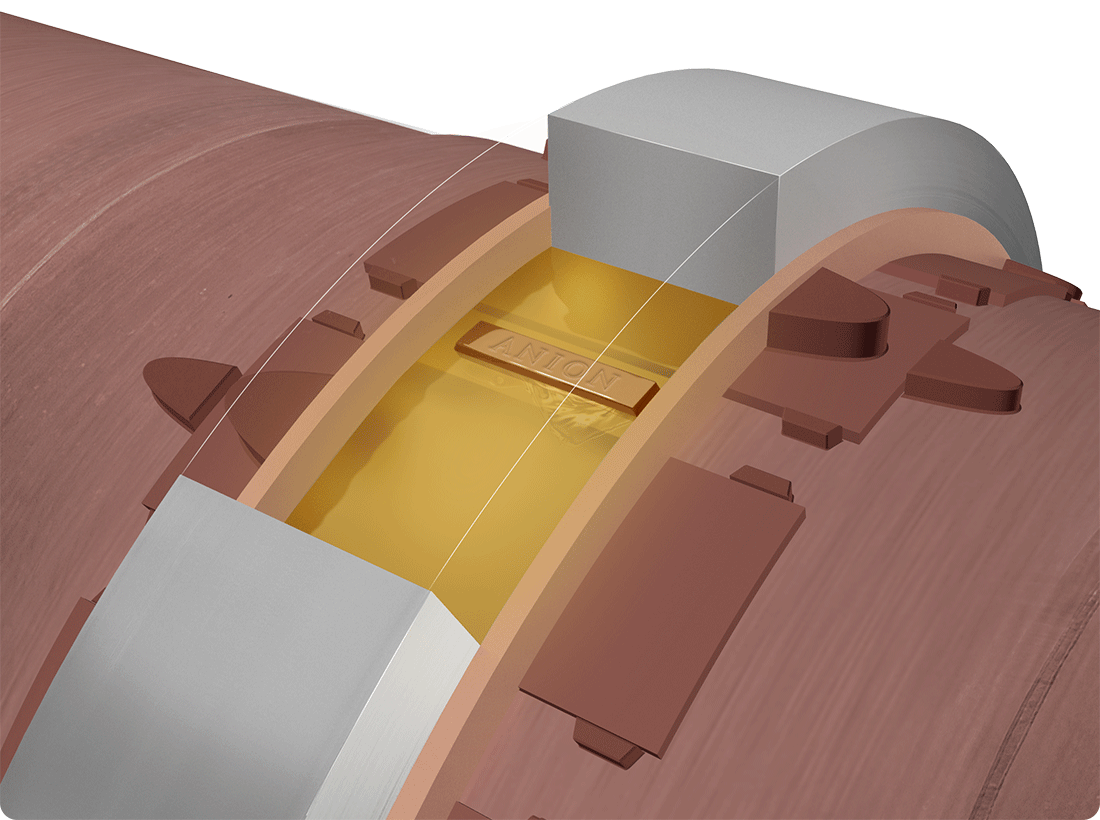

Upon placement between the tyre and the kiln shell, the carrying agent undergoes melting, releasing the lubricants. The kiln’s rotation then distributes the lubricants over the filler bars and inside the tyre bore.

Practical & Efficient

Anion® Slick Bar® simplifies and expedites the tyre bore lubrication process. Achieving homogeneous lubrication no longer depends on the crew’s skills; all it takes is placing the bar between the tyre and the shell.

Anion® Slick Bar® is a solid high-temperature lubricant bar designed to melt upon contact with the hot surface of a kiln or dryer shell. Anion®’s patented blend of graphite, mineral, and metal lubricants is suspended in a solid polymer binder. Positioned between the tire and the kiln shell, the carrying agent melts, releasing the lubricants, which are then distributed over the filler bars and inside the tire bore by the rotation of the kiln.

Anion® Slick Bar® melts at 50°C and possesses an auto-ignition point of 540°C. It is the only kiln lubricant bar that will NOT AUTO-IGNITE during application.

Anion® Slick Bar® employs principles of lubricity and physics to ensure proper lubrication of kiln and dryer tyres. Initially, it incorporates high-quality, non-petroleum, synthetic lubricants. Additionally, it includes a fine metal powder that takes advantage of the lubricating benefits of dissimilar metals.

Once melted, it utilizes the motion of the kiln to disperse its lubricants to the mating surfaces of the tyre bore and kiln shell. As the lubricants are distributed by the kiln’s motion, a thin, temperature-resistant film forms, creating a lubricating barrier between the moving surfaces. Simultaneously, it fills the microscopic imperfections typical on metal surfaces.

- Lubricate all tyre bore homogeneous

- Reduce kiln lubrication time and effort

- Maintain creep

Protect the shell during start-ups and shutdowns

- Increase Wear Pad Life +50%

- Minimize / Eliminate Weld fractures

- Extend Refractory Life

- Minimize Shell Ovality