On Site Machining & Grinding Services

for Tyre, Roller and Thrust Roller at up to 3,5 rpm

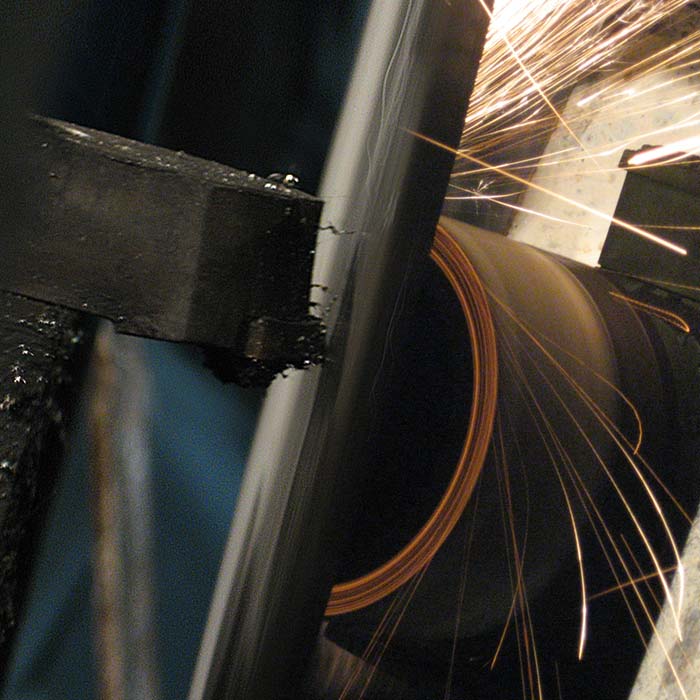

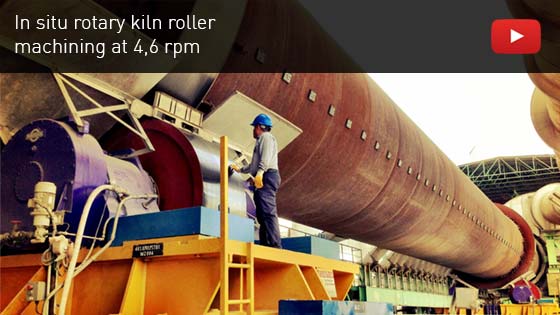

Özek Makina offers on-site machining and grinding services for the tyres, rollers, and thrust rollers of rotary kilns, rotary coolers, dryers, granulators, and agglomerators across industries such as cement, gypsum, fertilizer, feed, and petrochemicals. Our capabilities include simultaneous machining and grinding of tyres and rollers, with the capacity to work at up to 3.5 rpm for rotary kiln tyres and up to 5.0 rpm for rollers. Utilizing our patented mobile machining and grinding technology, we can effectively address deep pitting, as well as conical, concave, convex, or wavy wear profiles.

Service at 3,5 rpm

We have the capability to resurface your tyres and rollers while the kiln operates under normal conditions. In certain instances, there is no requirement to stop or even slow down the kiln.

Machining & Grinding Together

Our patented mobile machining and grinding technology enables us to address surface issues in tyres, rollers, and thrust rollers at any level.

Following the Diameter

We conduct measurements and provide reports on the diameter and local deformation before, during, and after our resurfacing services, guiding our decisions for any subsequent necessary actions.

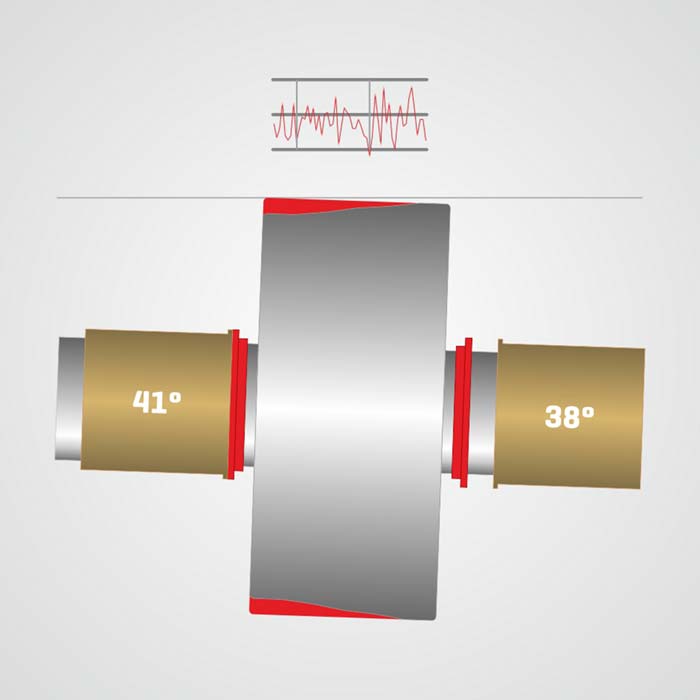

Alignment After Resurfacing

If required, we adjust the roller skew to accommodate the machined new diameter. Additionally, we offer combined services for hot kiln alignment and on-site resurfacing.

Experience

Since 1968, Özek Makina has delivered over 700 distinct services to 140 plants spanning 30 countries, amassing remarkable experience in rotary kiln services.

Self-Devotion

We are on-site with a team capable of assessing the problem from various perspectives. We dedicate ourselves to meticulous analysis and strive with heightened effort to refine the solution, all while aligning our work seamlessly with the planned revision schedule.

On Site On Time

Our primary objective is to assist you in maintaining the kiln’s rotation seamlessly. We prioritize swift arrival at the plant with our tools within a matter of days. Our engineering and logistics team is prepared to respond promptly to any international call.

World Wide Service

Having successfully serviced nearly all Turkish plants, we take pride in extending our services to over 140 plants across 30 countries, spanning a broad geographical range from America to Vietnam, and from Argentina to Indonesia. We ensure 100% customer satisfaction.