Roller and Bearing Replacement Services

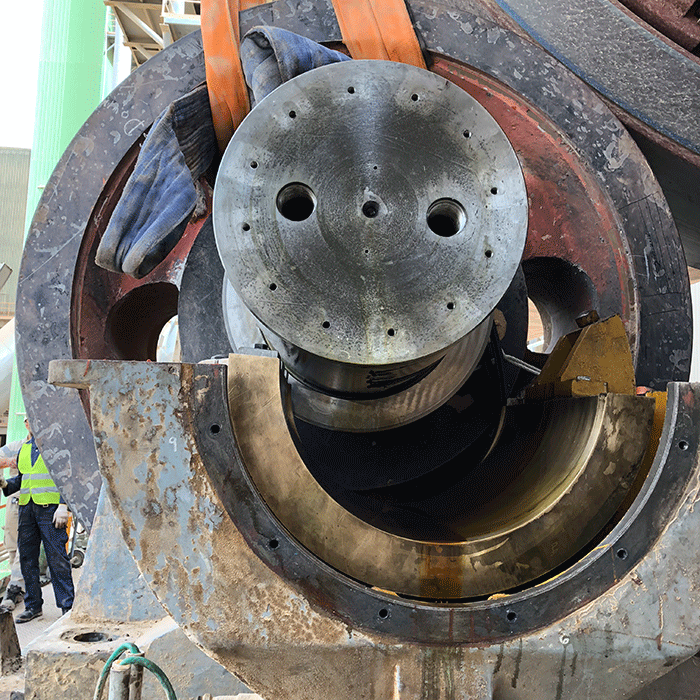

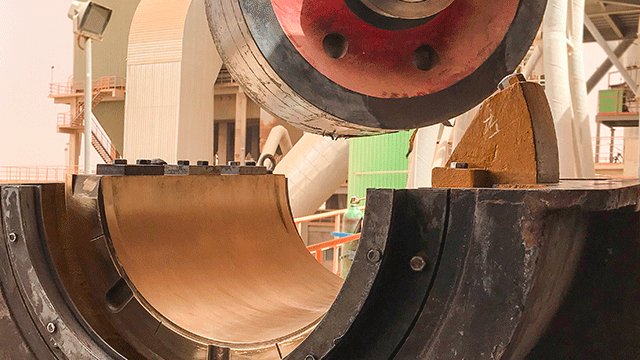

The rollers of your rotary kiln may undergo damage due to misalignment, excessive load, or poor material quality, with issues such as shaft cracks, small pittings, or larger surface cracks being potential causes. Our supervision services for roller and bearing replacement commence with an examination of the old roller to identify possible causes of damage and to confirm the need for replacement.

Following this, we inspect the new roller’s shaft surface quality and diameter for comparison. Upon dismantling the old roller, we assess the old bearing to determine if replacement is necessary and prepare the new bearing accordingly. After cleaning the new bearing and placing it in the housing, we reposition the roller to its newly calculated position.

Once the kiln begins rotating, we closely monitor the reactions of the new bearings and make precise adjustments during both the bearing temperature and kiln’s axial migration periods.

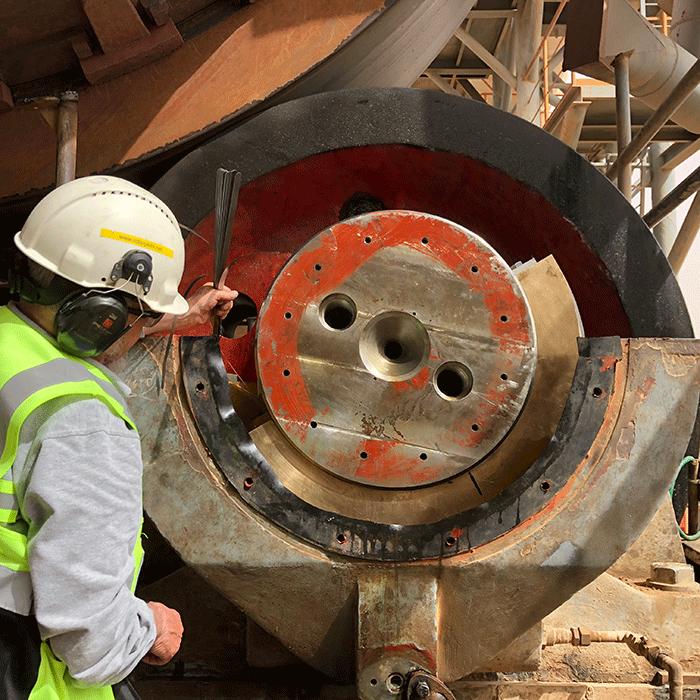

Highly Damaged Roller

Due to various reasons, such as shaft or surface cracks, any of your rollers may eventually become unusable. In such cases, you may find it necessary to replace the entire roller, including the bearing. Alternatively, you might choose to retain the bearing while replacing only the roller.

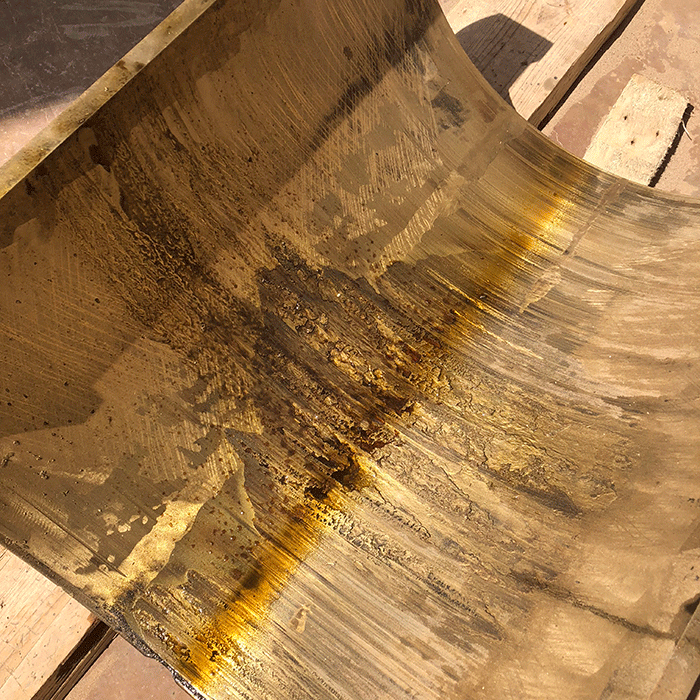

High Bearing Temperature

Elevated bearing temperatures, resulting from friction between the roller shaft and the bearing, may prompt you to consider replacing only the bearing before it causes irreversible damage to the roller shaft.

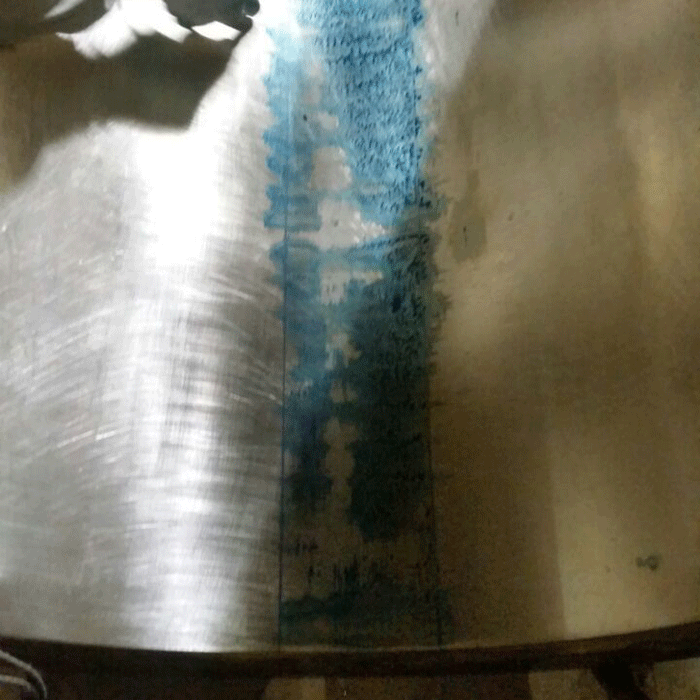

Bearing Preparation

Even with all dimensions matching, it is crucial to meticulously clean a new bearing to establish a precise shaft relationship according to required standards. This process ensures an efficient oil flow and oil film, preventing any unforeseen friction.

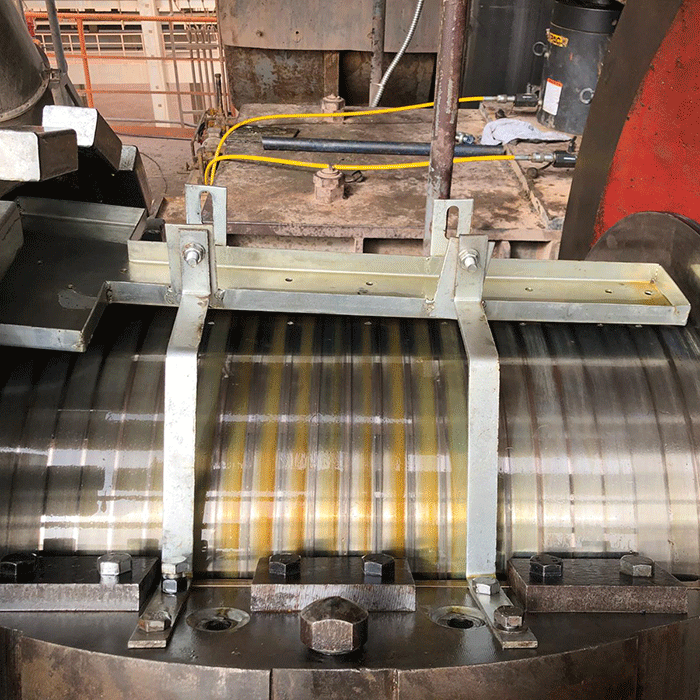

Positioning the Roller

A comparison of the diameters of the old and new rollers is essential. The necessary position for the new roller should be calculated, and the roller must be carefully placed in its designated position to maintain the center of the tyre at the same level.

Experience

Since 1968, Özek Makina has delivered over 700 distinct services to 140 plants spanning 30 countries, accumulating significant experience in rotary kiln services.

Self-Devotion

We are on-site with a team capable of assessing the problem from various perspectives. We dedicate ourselves to thorough analysis, exerting extra effort to refine the solution and align our work seamlessly with the planned revision schedule.

On Site On Time

Our primary objective is to assist you in maintaining the kiln’s rotation without any hassle. We prioritize swift arrival at the plant with our tools within a matter of days. Our engineering and logistics team is prepared to respond promptly to any international call.

World Wide Service

Having successfully served nearly all Turkish plants, we take pride in extending our services to over 140 plants across 30 countries, covering a broad geographical range from America to Vietnam, from Argentina to Indonesia. We ensure 100% customer satisfaction.